The COVID-19 pandemic has necessitated the rapid improvement of new systems for vaccine growth and shipping. A single vital enhancement has stemmed from the require for largescale generation of mRNA-based mostly vaccines encapsulated in lipid nanoparticles (LNPs), enabling fragile mRNA-centered vaccines to greater combine into patients’ cells.

KNAUER has been at the forefront of this vital growth in the fight versus COVID-19, with the company’s Impingement Jets Mixing technologies supplying a system for the superior movement production of lipid nanoparticles.

We not long ago spoke to Dr. Paul Pietsch from KNAUER about the company’s track record, its selection of specialisms and its revolutionary operate to aid the largescale manufacturing of LNPs whilst assembly the stringent regulations and exacting needs of the biopharmaceutical industry.

You should could you make clear what KNAUER can provide to engineers and field gurus?

KNAUER has been developing significant-top quality scientific devices since 1962. We are an professional associate in the supply of gear for use in the pharmaceutical industry, such as liquid chromatography methods and technological innovation for lipid nanoparticle generation and encapsulation.

We are very pleased to have quite a few authorities in our group, enabling us to create revolutionary and person answers designed all-around just about every of our customers’ exclusive worries. In addition to this, we supply engineering products and services to create methods that meet the specific requires and demands of our end buyers.

What can KNAUER provide the pharmaceutical industry that its competition, probably, simply cannot?

There are lots of firms out there providing tools and methods to the pharmaceutical business, and they arrive in a lot of styles and measurements even so, KNAUER still has a one of a kind offering for our associates in the pharmaceutical industry.

To begin with, we are an set up enterprise that has been functioning for virtually 60 many years. All of these decades of expertise mean that we are well versed in delivering custom made program answers to our companions.

Next, we are neither much too massive nor as well smaller. Our medium organization sizing means that we can react flexibly to the demands of our prospects – like we did for the duration of the coronavirus pandemic with our lipid nanoparticle technology – although still having the manpower to supply solutions at velocity.

Our 3rd exceptional strength is that we create all of our devices in-residence at our headquarters in Berlin. Our on-web page creation will allow us to promptly adapt our present units to our customers’ desires applying our individual CNC production, products assembly line and application growth workforce.

For illustration, if a customer wants a distinctive valve to entire a procedure that is not obtainable on the marketplace, our development group can style and design the expected element in accordance to their specifications.

Pursuing style, the aspect can then be manufactured by our CNC output and hooked up to the procedure. Our software package staff can then system any capabilities essential to combine the valve. This entire procedure can quickly be carried out in-dwelling, depending on the time requires of our consumers.

To summarize all of this – KNAUER can deliver out-of-the-box, custom made alternatives for the pharmaceutical marketplace as and when essential.

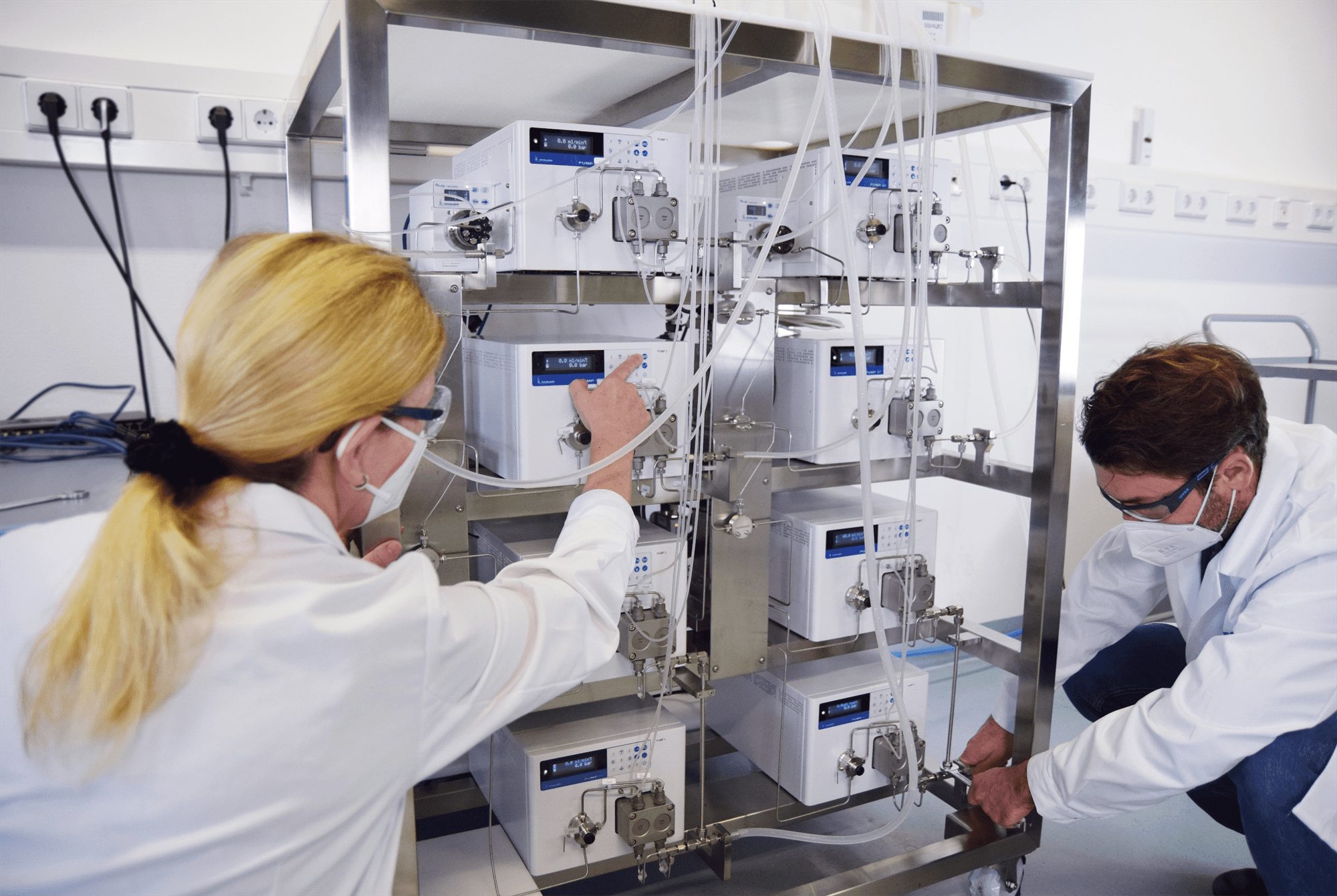

An example of a personalized system built by KNAUER – this procedure takes advantage of 16 pumps for the purification of monoclonal antibodies.

mRNA vaccines have at present been generating headlines – how do KNAUER assist in their production?

The most acceptable delivery structure for mRNA-based vaccines is lipid nanoparticles (LNPs). LNPs encapsulate the mRNA used in coronavirus vaccines and the ensuing lipid capsule guards the fragile mRNA from degradation, raising integration into the patient’s cells.

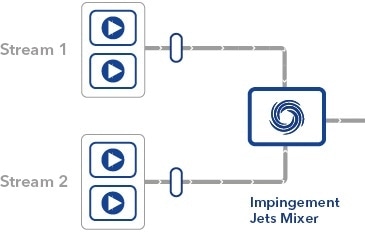

The mRNA encapsulation course of action utilizes Impingement Jets Mixing technology, in which two streams (1 containing lipids and a different that contains an aqueous answer of mRNA) collide at high velocity in a jet mixing chamber – it is this action that KNAUER’s engineering is included in.

With our experience in programs engineering and higher-stress dosing, we had been ready to present a main pharmaceutical producer the technological know-how they demanded for the higher move production of lipid nanoparticles.

Our Impingement Jets Mixing Skids have proven exceptional efficiency in the significant-scale generation of mRNA encapsulated in lipid nanoparticles for use in coronavirus vaccines. These are now currently being applied globally in related programs.

Schematic diagram displaying the mixing procedure transpiring within an IJM technique.

Are there any breakthroughs or developments that KNAUER is groundbreaking that you are especially energized about?

The Impingement Jets Mixing (IJM) Skids we covered in the very last problem are what excites me most right now.

Prior to the coronavirus disaster, equipment for the output of LNPs only existed at a laboratory scale, which means the largescale creation of mRNA encapsulated in LNPs was not however probable.

The coronavirus crisis intended that technologies that could be utilized in the big scale output of mRNA-centered vaccines all of a sudden became urgently crucial. This posed a problem as the big scale generation of this sort of methods experienced not however been carried out, and the lab-scale production of LNPs was not effortlessly scalable.

To solve this challenge, we mixed quite a few lab-scale models in parallel to produce our IJM Skids, which could then be used for LNP generation at a massive scale. This seems like a basic remedy, and, in concept, it is. Even so, it demanded a higher degree of finetuning and knowledge to implement this according to the polices and needs of the biopharmaceutical industry.

Our existing units had to be tailored for pharmaceutical output, which incorporated the structure of tailor made manifolds for inlets and shops, movement route optimization, structure adaptation to fulfill clean up space C necessities and the provision of interfaces for our customers’ individual PLC units.

We are happy to have played a position in generating record with coronavirus mRNA vaccines, becoming the to start with example of the use of mRNA-based LNP vaccines. We’re even much more happy to have done all of this less than unbelievable time tension, serving to to provide a coronavirus vaccine when the world essential it most.

KNAUER’S IJM Skids have performed these a crucial position in the creation of mRNA coronavirus vaccines in Germany that the German Chancellor herself frequented the corporation in September 2021.

What forms of projects in the pharmaceutical field has KNAUER been concerned in?

Thanks to the rigorous confidentiality required by the biopharmaceutical sector, we just cannot name any names. We are, on the other hand, fired up to be working with one of the greatest suppliers of mRNA coronavirus vaccines.

Our 1st undertaking with this lover was just one of the most exciting assignments for our engineering-to-purchase support to day. This is simply because of the time strain and the reality that the system we were being creating had never ever been generated right before.

The urgent want for the creation of mRNA vaccines intended that a normal venture circulation – with scheduling, engineering, offer you and buy stages – could not be utilised. Production started immediately next the first ask for, while our engineers built the system in parallel to production with our purchaser.

Thanks to the fast-relocating requirements of the venture, we experienced to stay versatile. Sometimes do the job we had completed a person working day wanted to be reversed or modified the next working day. Next 3 months of very focused enhancement, we have been proud to see the procedure in generation.

It’s important to mention that our offerings for the pharmaceutical industry go outside of our IJM Skids. We also supply finish solutions for the purification of other active pharmaceutical substances (APIs).

We are normally approached by shoppers who know their target API and know how to develop it but absence the capacity to purify it – this is in which KNAUER can support.

When approached by this sort of a customer, we assistance them from the bottom up. We start off with a column screening, then build a system and optimize it at the lab scale. Utilizing these final results, we can then operate the purification applying our simulated transferring bed (SMB) technique, which makes it possible for for ongoing purification.

Next this scale-up, our shopper can then start off developing API at a pilot scale.

How does KNAUER assist GMP compliance for pharmaceutical companies?

KNAUER provides expertise and means to pharmaceutical brands to enable them implement GMP-compliant pharmaceutical production. Our customers frequently have specific specifications for the KNAUER hardware that they are interested in, and these are normally described in their unique Person Requirement Requirements (URS).

We explore the URS with our consumers and assistance be certain that their polices continue being up to day, assisting producers supply items that satisfy their finish users’ specifications and adhere to all required safety standards.

Our GMP companies are centered on our components and program options. Products basic safety is supported by documentation on solution conformity and the compliance of supplies employed as wetted components.

High quality regulate is ensured by set up and operational qualification, as well as general performance verification. Moreover, a factory acceptance take a look at (Body fat) and a aspect acceptance test (SAT) are conventional GMP solutions.

We also location a great emphasis on individual teaching, like software program, hardware, maintenance and service training deals.

Installation and tests of an IJM Skid for the encapsulation of API in lipid nanoparticles

What are some of the new troubles that experience the pharmaceutical sector in the wake of the COVID-19 crisis, and how will KNAUER support tackle them?

From the COVID-19 disaster, we have discovered to be open up to new systems and that, for us, being rapid and versatile are the keys to good results.

In a greater point of view, there is a probability that the coronavirus disaster has accelerated a terrific modify in the vaccine landscape – a migration to mRNA-based vaccines seems to be on the horizon.

mRNA vaccines have the unique advantage that they can be swiftly modified in response to virus mutations, and this reward could see them beginning to dominate the area in the coming several years.

LNP-encapsulated mRNA technologies does not stop there possibly – we hope to see the engineering staying made use of in gene therapy, when LNPs, in typical, can be used for the shipping of other fragile APIs. We are at the commencing of a new period in drugs and we’re very pleased to be at the forefront.

We’re fired up to be portion of this revolution and seem forward to supporting generate this health-related revolution with our tailor-designed answers for pharmaceutical processing and generation.

How does KNAUER intend to operate alongside people in a put up-COVID world?

We intend to operate along with individuals as we did just before. For us, shut collaboration with our prospects is the key to developing products and devices that our shoppers are truly pleased with.

We have a devoted group of professionals from hardware development to top quality professionals accessible through the total layout system, and these experts are on hand to assist our prospects with the know-how they will need to uncover the best remedy to their troubles.

About Dr. Paul Pietsch

Dr. Paul Pietsch examined Food items Technological know-how at the Anhalt College of Applied Science in advance of going on to full a chemistry Ph.D. at the Complex University of Berlin. Subsequent completion of his doctorate, Dr. Pietsch joined the team at KNAUER as a product supervisor for their constant chromatography devices. Following 3 and a fifty percent years in this function, he moved on to develop into the head of engineering options throughout the complete organization.

About KNAUER Wissenschaftliche Geräte GmbH

KNAUER Wissenschaftliche Geräte GmbH is a center-sized firm that has been building, manufacturing and distributing laboratory instruments around the globe since 1962.

With much more than 130 staff, Knauer is 1 of the well-founded suppliers of HPLC instruments, SMB systems, and osmometers. Product or service portfolio includes really compact HPLC answers, UHPLC techniques for significant-resolution assessment, preparative HPLC instruments, procedure LC equipment for the purification of substances in the kilogram scale, autosamplers, column thermostats, degassers, detectors, dosing pumps, eluent mixers, flowmeters, LC columns, and equipment and spare elements, among other folks.

The source of Knauer’s success is a lot of world’s firsts that have won far more than 20 awards for innovation.